In the pulp and paper industry, which is one of Sweden’s most important export industries, the annual global energy consumption is more than 6 EJ, with 75% from thermal energy (fossil fuels and biomass) and 25% electricity. This is more than 1% of the world’s total energy consumption.

The main challenge is to design biomaterials, not only to increase the efficiency of current paper production, but also to provide new stronger and more resistant materials to replace steel, plastics, and other materials. This will have a large impact on energy usage and sustainability both directly (less energy used for production) and indirectly (replacing traditional materials with better ones).

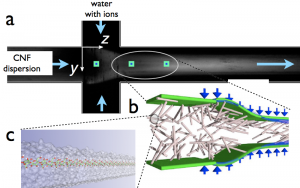

Cellulose nano-fibrils (CNF) constitute one example of raw material originating from trees via pulp and that is biodegradable. They have been used to create strong films and filaments as well as functional materials. However, in order to turn these scientific breakthroughs into industrially viable products, we need efficient processing and control of how the properties of the final material react to humidity. Both of these critical aspects originate from molecular interactions (figure c) on the fibril surface that determine the amount of aggregation at the meso-scale (figure b); this in turn influences e.g. the density fluctuations of the larger aggregate particles and the global transport properties of the suspension (usually modelled at the continuum scale by rheological constitutive relations). To be able to alter these properties, we need to model the bulk and interface properties at all the three different length scales (figure ).

Challenges include: i) processing at high concentrations to drastically reduce the power needed for pumping, mixing and heating; ii) more efficient drying, where modified molecular interactions can be used to reduce water content before thermal drying without degrading the bulk properties; and iii) control of the interactions between the final material and water, to reduce the sensitivity to humidity of the material, and remove the need of protective surface treatments.